Based on a video titled “The interesting engineering behind the SHAPE of Train wheels!” by Lesics, this article aims to shed light on the fascinating engineering principles that dictate the conical shape of train wheels. The video, which has garnered over 30 million views, delves into the two major accomplishments achieved by this seemingly simple design: self-centering of the wheels and differential action during turns.

Contents

- The Self-Centering Marvel

- Differential Action During Turns

- Extra Safety Features

- The Forces at Play

- The video

The Self-Centering Marvel

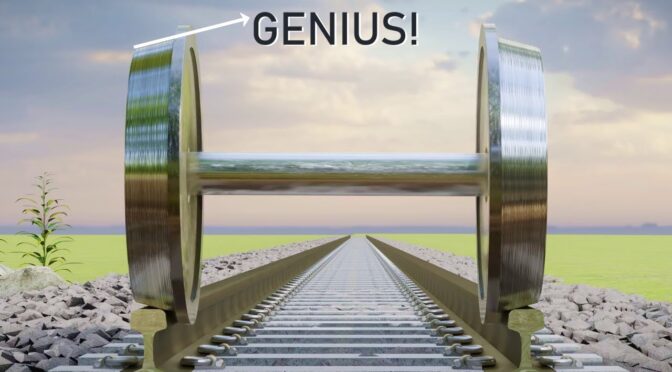

Train wheels are not perfectly cylindrical; they are slightly conical. This conical shape serves a critical function: it corrects the course of the train towards the center of the track. When a train wheel set is slightly tilted, the forces acting on it change in such a way that a net force is generated towards the center. This self-centering force ensures that the wheels automatically return to the center of the track, thus maintaining the train’s stability and preventing derailment. The video demonstrates this with a simple experiment using glued paper cups, showing how the conical shape produces a self-centering force that keeps the train on track.

Differential Action During Turns

Another fascinating aspect of the conical shape is its role in enabling differential action when the train takes a turn. In a turn, the wheel on the outer side of the curve has to travel a greater distance than the wheel on the inner side. The conical shape allows for this by causing the wheels to slide slightly, changing the radius at the point of contact. This differential action is achieved without separating the wheels or turning them at different speeds, which is a common practice in cars. The video explains that the conical shape alone allows the train to navigate turns effectively, highlighting the ingenuity of the engineers who designed it.

Extra Safety Features

In addition to the self-centering and differential action, train wheels also have flanges on both sides as an extra safety feature. These flanges serve as a backup to ensure that the train remains on the track, adding another layer of security to the already robust design. The video points out that these flanges are not the primary mechanism for keeping the train on track but act as a supplementary safety measure.

The Forces at Play

During a turn, a force is generated that supplies the centripetal force needed for the turn. This ensures that the wheels do not slide back to the center during cornering, thus maintaining the train’s stability. The video uses force analysis to explain how these forces interact and contribute to the train’s overall performance.